Plastic pyrolysis

An increasing environnemental problem

Plastic is a cheap and efficient material. Demand is strong and growing. However, plastic is considered one of the biggest environmental concerns. Global production of plastics increased from 1.5 million tonnes in 1950, 15 million in 1964 to 322 million tonnes in 2019 (around 18% in Europe) and is expected to double in the next two decades. It is estimated that 8 Mt/year of plastics end up in the oceans, causing a devastating effect on wildlife and the food chain.

Plastic waste is both a huge untapped resource and a growing global environmental problem. There is an opportunity to replace the growing consumption of fossil fuels for plastic production by creating high-value products from plastic waste for the circular economy and decarbonization of industry.

Plastic pyrolysis oil

Plastic pyrolysis oil is a high energetic liquid that can be used in standard refinerie process. It allows to produce an alternative fuel from waste.

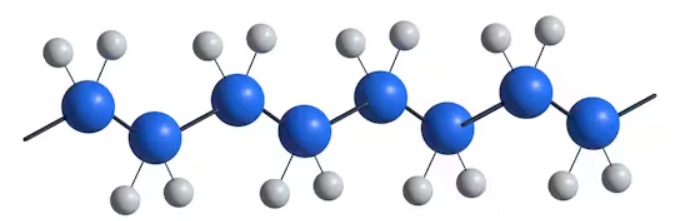

Plastic pyrolysis gas

Plastic pyrolysis gas contains high amount of Hydrogen and Methane, which can be separated and used as a substitute to natural gas or for Hydrogen applications. It contains also high amount of olefines which can serve to produce new plastic.

References

Since 2022, ETIA is involved in the European project Plastics2Olefins (P2O). The project gathers 13 partners and aims at demonstrating the production of new plastic from non recyclable plastic streams. ETIA has provided a pilot operated by Repsol. In the next steps of the project, a semi industrial plant will be constructed and operated to demonstrate the whole process.

ETIA has also developped a demonstration plant with a capacity of 80kg/h for plastic pyrolysis. In collaboration with an industrial partner, this unit will be used to demonstrate the production of high quantity and high quality pyrolysis oil. This is a promising way to valorize plastic wastes into alternative fuel.