Pyrolysis – definition

Pyrolysis is a thermochemical treatment, which can be applied to any organic (carbon-based) product. It can be done on pure products as well as mixtures. In this treatment, material is exposed to high temperature, and in the absence of oxygen goes through chemical and physical separation into different molecules. The decomposition takes place thanks to the limited thermal stability of chemical bonds of materials, which allows them to be disintegrated by using the heat.

Thermal decomposition leads to the formation of new molecules. This allows to receive products with a different, often more superior character than original residue. Thanks to this feature, pyrolysis becomes increasingly important process for today industry – as it allows to bring far greater value to common materials and waste.

Pyrolysis is frequently associated with thermal treatment. But in contrary to combustion and gasifications processes, which involve entire or partial oxidation of material, pyrolysis bases on heating in the absence of air. This makes it mostly endothermic process that ensure high energy content in the products received.

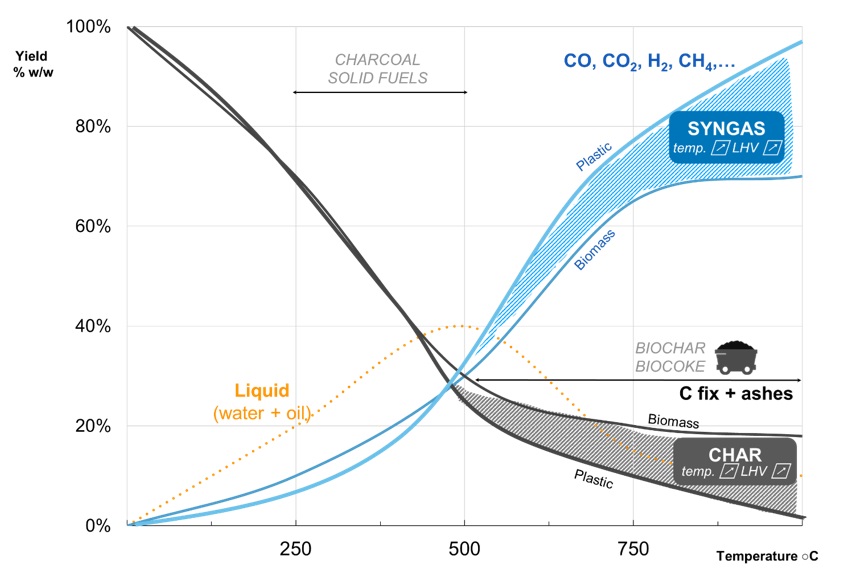

Pyrolysis products always produce solid (charcoal, biochar), liquid and non-condensable gases (H2, CH4, CO, CO2, CnHm). As the liquid phase is extracted from pyrolysis gas only during it’s cooling down, in some applications, these two streams can be used together when providing hot syngas directly to the burner or oxidation chamber.

What influences pyrolysis process results?

- treated material composition – each of the major constituents of biomass and waste feature different temperatures of thermal decomposition, which means they contribute to the results of process in different way. Due to high diversity of material compositions, it is recommended to perform a pilot tests to forecast the pyrolysis process performance in most accurate way.

- temperature of process – temperature has a major influence on the treatment results. Higher temperatures of pyrolysis provide greater quantity of non-condensable gases (syngas, synthetic gas), while lower temperatures favour the production of high quality solid product (charcoal, bio-coal, torrefied fuels). Temperature is a factor fully controllable in Biogreen® process thanks to electrically heated screw conveyor that allows precise setup of treatment conditions.

- residence time of material in the pyrolysis chamber – residence time influences the degree of thermal conversion of received solid product. Residence time can be precisely controlled in Biogreen® process by changing the rotation speed of screw conveyor (Spirajoule®) transporting material along the reactor.

- particle size and physical structure – it influences the speed in which material is subjected to pyrolysis. In general, lower particle size materials are quicker affected by the thermal decomposition, which can result in different yields.