Biogreen

Presentation

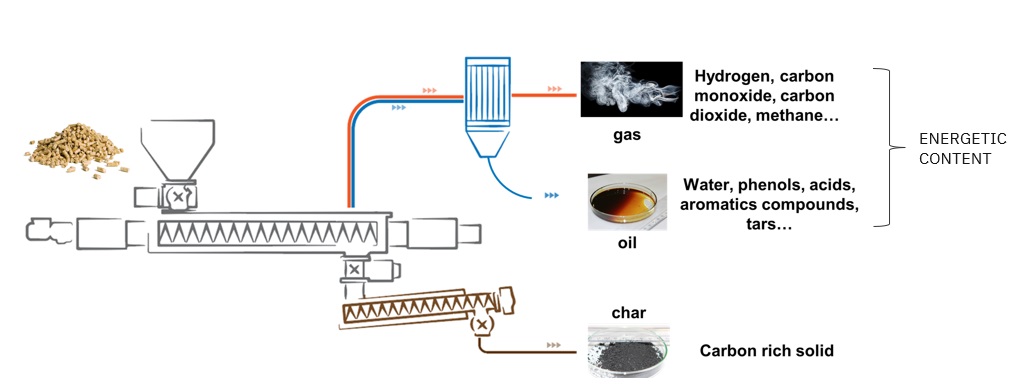

Biogreen pyrolysis process is based on electrically heated screw conveyor (Spirajoule®), designed for advanced thermal treatment in temperatures up to 750°C. The system consists of a feeding system, pyrolysis reactor and char cooling system.

Processed product temperature is precisely controlled basing on the temperature settings. The dwell time of material inside Spirajoule® reactor is regulated by screw rotation speed. Thermal conversion is performed in oxygen-free (pyrolysis) atmosphere in unique construction of equipment, which guarantees a constant quality of product obtained from the treatment.

Biogreen® module is designed to process up to 1t/h. Actual mass capacity is linked to the applied treatment time (« residence time ») of raw product and its apparent density (kg/m3). Residence time of material is set up in Biogreen® control panel and regulated by screw rotation speed. For obtaining higher capacities, several reactors are placed in paralell.

Biogreen® is innovative, patented pyrolysis process operating since 2003. Since more than 2 decades, our solution works for converting biomass, plastics, and waste into energy and useful products.

What makes the Biogreen pyrolysis technology unique?

- Industrial pyrolysis operating for over 2 decades: first unit commissioned in 2003

- Continuous and fully automatic process of pyrolysis

- Highest quality of products

- Full and reliable control of treatment conditions

- Easy change of operating conditions

- Worldwide availability

- Variety of sizes and configurations

- Small footprint; « lean & mean » equipment

Containerised pyrolysis unit

Equipment can be delivered in containerised modules that allow to present a quick and ready to use version of the Biogreen® pyrolysis plant.